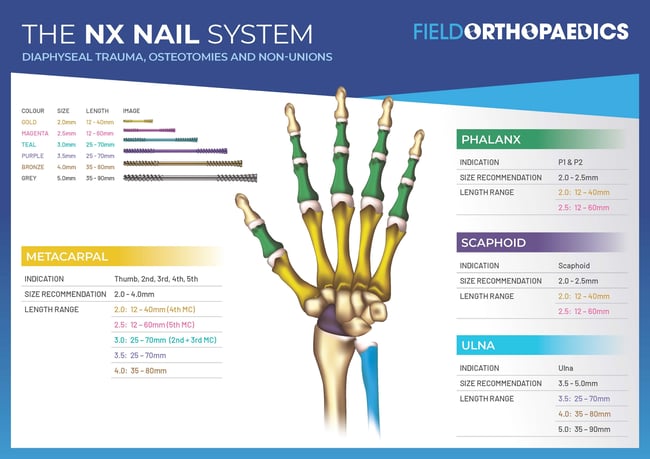

The NX Nail System

Overview

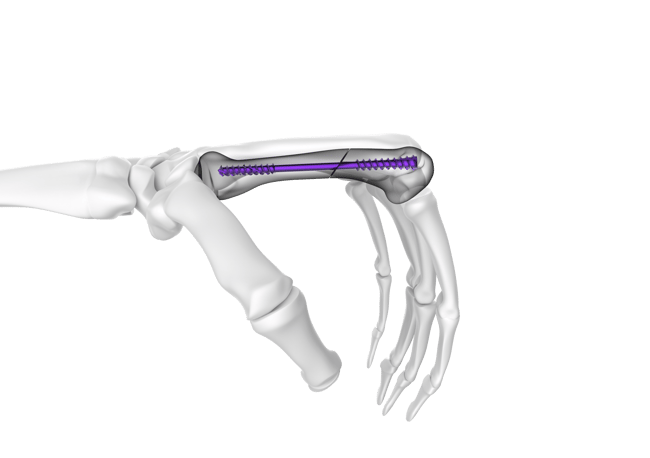

Designed in collaboration with renowned US orthopaedic hand surgeons from leading hospital training institutions, NX Nail has a partially threaded design with a wide head, narrow waist, and smooth shaft.

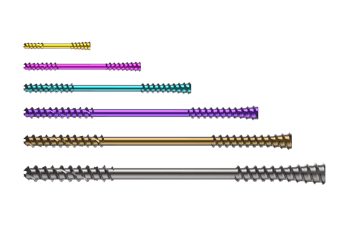

Primary stability is achieved by the interference fit of the compaction taper head, which, when combined with distal fragment control from the leading tip, provides rotational and longitudinal control without compression. In addition, an extensive size range made from biocompatible titanium alloy (Ti-6AI-4V ELI) offers surgeons flexibility to treat a variety of patient anatomies.

Available as a traditional reusable system with non-sterile implants and instruments or as a fully sterile system with single-use instruments and individually packed implants (US Only), the NX Nail system can meet your needs.

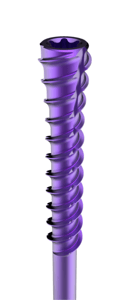

Compaction Taper Head

- Designed from statistical shape models of real CT scans to be anatomically contoured and maximise engagement.

- Engineered to circumferentially displace and compact cancellous bone to increase relative density and load the bone.

- Strong fixation generated by interference fit between implant threads and bone for rotational control and longitudinal stability.

- Features a constant screw pitch for controlled advancement.

Smooth Shaft

- Facilitates passage through the isthmus and respects the viscoelastic properties of bone with no diaphyseal fixation or stuffing.

- No reaming or cortical contact reduces endosteal irritation and disruption to blood supply.

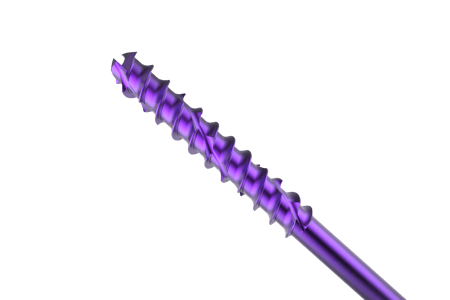

Precision Leading Tip

- Designed for ultra-low insertion torque with a high precision, multi-start, self-cutting design.

- Fine thread pitch provides distal fragment control and a constant screw pitch allows for controlled advancement.

Titanium Alloy

- Made from a biocompatible Ti-6Al-4V ELI that avoids common metal allergies and is resistant to corrosion.

- Provides strength and facilitates a large size range.

- Has a modulus closer to bone than other medical grade alloys.

Non-Compressive Design

- Matching thread pitch on the head and tip provide a neutral compression profile.

- Embodies the AO principles of relative stability1 and maintains length, restores version, and controls angulation while bridging the fracture and controlling micromotion for indirect healing and callus formation.2,3,4

Benefits

The NX Nail provides rigid fixation, stability and an environment for bone healing which accelerates return to function and mobility.1,4

With a minimally invasive surgical approach that avoids extensive soft-tissue dissection and no hardware profile, NX Nail is suitable for high-demand patients requiring a short recovery before returning to work and daily activities.1,4,5

NX Nail offers a reliable alternative to K-wires and plates with minimal complications and a short learning curve.6 A minimally invasive surgical approach avoids extensive softtissue dissection6 while buried hardware avoids adhesions.7

What are the risks associated intramedullary nailing?

Contraindications, potential complications, warnings and precautions:

In any surgical procedure, the potential for complications and adverse reactions exists. Contraindications include cases of inflammation, cases of active or suspected sepsis / infection and osteomyelitis, patients with certain metabolic diseases and applications that are not defined by the indications.

The risks and complications with these implants can include loosening, deformation or fracture of the implant, acute post-operative wound infections and late infections with possible sepsis, thrombosis and embolism, wound hematoma and delayed wound healing, temporary and protracted functional neurological perturbation, tissue reactions resulting from allergy or foreign body reaction to dislodged particles and corrosion with localised tissue reaction and pain. All complications listed here are not typical of the Field Orthopaedics (FO) Bony Trauma Extremity System (BTES) but can be in principle observed with any implant.

Warnings and precautions related to the use of the FO BTES include; re-operation to remove or replace implants may be required at any time due to medical reasons or device failure, if corrective action is not taken complications may occur; use of an undersized screw/nail in areas of high functional stresses may lead to implant fracture and failure; plates and screws, wires, or other appliances of dissimilar metals should not be used together in or near the implant site; the FO Screws, NX Nails, Plates, Pins and K-Wires, and FO drill bits are intended for single use only, re-use may cause product failure and could lead to disease transmission; instruments, guide wires and screws/nails are to be treated as sharps; Field Orthopaedics branded instrumentation is recommended for use in conjunction with FO BTES Implants.

These devices have not been evaluated for safety and compatibility in the MR environment. For further details, please consult the instructions for use.

Case Reports

References

- AO Foundation. Basic principles of intermedullary nailing. AO Surgery Reference. [Online] https://surgeryreference.aofoundation.org/ Orthopaedic-trauma/ adult-trauma/basic-technique/basic-principles-of-im-nailing#nail-removal.

- Kodi Kojima and Robinson E Piers, Absolute and relative stabilities for fracture fixation: the concept revisited, October 2017, Injury, 48(2):S1

- Josefa Bizzarro and Pietro Ragazzoni. Four Principles of Fracture Mangement. Lecture. AO Foundation. AO Trauma.

- M.E. Müller, M. Allgöwer, R. Schneider, and R. Willenegger: AO Manual of Internal Fixation, 3rd Edition. Berlin: Springer-Verlag. 1991.

- Rafael Diaz-Garcia, Jennifer F Walijee. Current Management of Metacarpal Fractures. Hand Clinic, November 2013, 29(4), pp. 507-518.

- Marco Guidi, Florian S Frueh, Inga Besmens, Maurizio Calcagni. Intramedullary compression screw fixation of metacarpal and phalangeal fractures. October 2020. EFORT Open Reviews, 5, 624-629.

- Michael Okoli, Rishi Chatterji, Asif Ilyas, William Kirkpatrick, Jack Abboudi, Christopher M Jones. Intramedullary Headless Screw Fixation of Metacarpal Fractures: A Radiographic Analysis for Optimal Screw Choice. 2022. HAND, 17(2), 245-253